1 Brief of Solder Wire

Solder wire is made of tin alloy and flux in two parts, the alloy is divided into tin and lead, lead-free flux evenly poured into the middle of the tin alloy. Different types of flux will be have different solder wire is to improve that in the welding process of secondary heat conduction, removal of oxidation, reducing the surface tension of the material to be welded, the surface of the welding material is removed, increasing the welding area. Solder wire is characterized by a certain length and diameter of the tin alloy wire, soldering the original electronic components can be used in conjunction with the electric iron or laser.

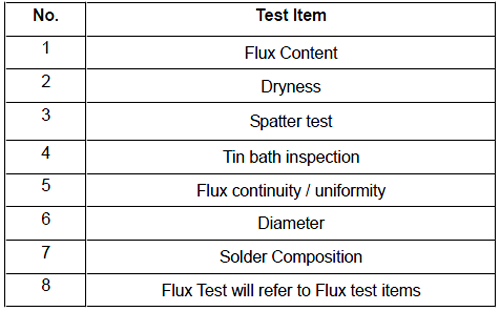

2 Key Test Items

3 Case Study

(1) The content of metal impurity is high;

(2) A lot of solder ball during use;

(3) Poor soldering

公众号

Add.(Office):16th Floor, Building AB, Southern Securities Building, No. 2016 and 2018 Jianshe Road, Jiabei Community, Nanhu Street, Luohu District, Shenzhen City, Guangdong Province

Tel.: +86-769-22247299 E_mail: Service@itstlab.com

Add.(Laboratory):1F, no.278, wentang shiyang street, dongcheng district, dongguan, guangdong.

Tel.: +86-769-22247299 E_mail: Service@itstlab.com

Add.: 407, 3 building, No. 3, Science Avenue,Guangzhou Science Park,Guangzhou City,P.R.China.

Tel.: +86-20-29862950 E_mail: Service@itstlab.com